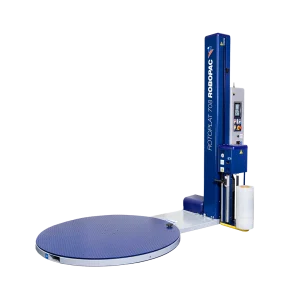

High-Speed Automatic Wrapping

Designed for high-throughput environments, the Technoplat 3000 can process up to 35 pallets per hour. Its rotary turntable system allows rapid wrapping cycles without compromising on load security or wrap quality, making it ideal for fast-paced logistics, manufacturing, and distribution settings.

Variable and Fixed Pre-Stretch Options

The machine supports both PGS and PVS film carriages. The PGS carriage offers a fixed 200% pre-stretch (with optional gears for 150%, 250%, or 300%), while the PVS carriage provides fully adjustable pre-stretch from 100% to 300% via the control panel. This flexibility allows businesses to optimise film usage and containment force for different load types.

Touchscreen Control with Cube Technology

A user-friendly colour touchscreen interface simplifies operation, allowing operators to adjust wrapping parameters and save custom programmes. Cube Technology ensures intelligent film application, optimising containment force for different zones of the load and significantly reducing film waste.

R-Connect Remote Monitoring and Support

R-Connect enables remote diagnostics, performance monitoring, and software updates. This cloud-based system helps reduce downtime, supports predictive maintenance, and provides actionable data insights, enhancing overall machine efficiency and peace of mind.

Flexible Integration and Load Compatibility

With adjustable working heights, up to 3100 mm maximum wrapping height (optional), and support for pallets up to 1500 kg and 1200×1200 mm in size, the Technoplat 3000 easily integrates into a wide range of automated lines. Optional accessories like top sheet applicators and roping systems further extend its adaptability.

Robust and Reliable Industrial Design

Built with a high-stiffness frame and reliable rotating components, the Technoplat 3000 is engineered for 24/7 industrial use. Low maintenance requirements and compliance with CE and UL standards ensure a long service life and safe operation in demanding environments.