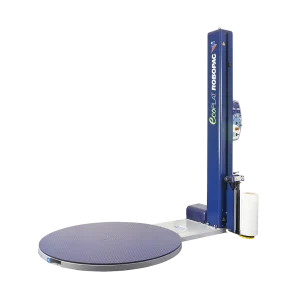

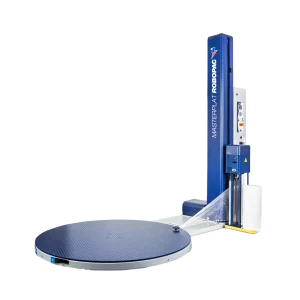

Advanced CUBE Technology

The Rotoplat 708 is equipped with Robopac’s exclusive CUBE Technology, offering intelligent film distribution and load containment. This minimises film use by up to 55%, ensures optimal wrapping strength, and reduces product damage. It also allows users to save up to 6 unique load configurations, enhancing flexibility and repeatability in complex operations.

Up to 400% Variable Pre-Stretch

Thanks to the PVS carriage with dual motor control, the film can be pre-stretched up to 400%. This drastically cuts material usage while maintaining secure load containment. The force applied to the load is electronically controlled and adjustable directly from the control panel for maximum precision.

User-Friendly 7-Inch Touchscreen

The 7-inch full colour touchscreen is designed for simplicity and speed. Intuitive icons and the MULTILEVEL CONTROL function allow for fast setup and real-time adjustments. Operators can quickly access settings, reducing training time and operational errors.

Robust Load Capacity and Construction

With a 65-inch turntable supported by 28 bearings and a maximum load weight of 2,000 kg, the Rotoplat 708 offers exceptional stability and reliability. It is capable of wrapping up to 40 loads per hour with consistent results, making it suitable for demanding production lines.

R-Connect Remote Monitoring

R-Connect provides real-time monitoring of machine performance via the cloud. With built-in connectivity and a 36-month data plan included, operators can remotely access machine data, receive maintenance alerts, and respond quickly to any operational issues, significantly reducing downtime.

Available in Stainless Steel for Hygienic Environments

For industries requiring strict hygiene standards, the Rotoplat 708 is available in a stainless steel version. Perfect for food processing, dairy, seafood, and pharmaceuticals, this version resists corrosion and is easy to clean, supporting safe and sanitary operations.