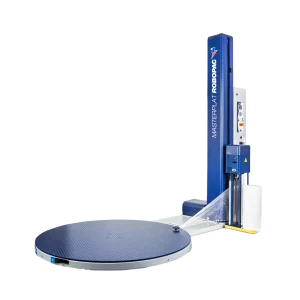

Reliable Semi-Automatic Operation

The Ecoplat Plus offers dependable semi-automatic wrapping for up to 25 loads per hour, making it ideal for smaller operations or those looking to streamline end-of-line packaging without high capital outlay. It is suitable for a wide range of industries including logistics, manufacturing, and retail.

FRD Film Carriage with Mechanical Brake

The FRD carriage ensures consistent tension with its mechanical brake, manually adjusted via a clear indicator. A tension release lever allows for easy film application to the pallet without altering the set tension, maintaining performance regardless of film reel size.

Simple and Intuitive Controls

Choose between the Base model with electromechanical buttons or the FRD model with a modern LED display and jog dial for precise control. Both offer essential adjustable parameters, such as top/bottom wraps, carriage speed, and turntable speed, supporting operator ease-of-use.

Robust Turntable Capacity

With a standard 1,500 mm diameter turntable (optional 1,650 mm) and a maximum load weight of 2,000 kg, the Ecoplat Plus handles heavy, standard-sized pallets effortlessly. The 28-bearing support system offers stable, low-noise operation.

Optional R-Connect Monitoring

Upgrade to R-Connect for remote monitoring, diagnostics, and performance optimisation. This Industry 4.0 feature enhances uptime, enables predictive maintenance, and provides real-time insights, ensuring smooth and cost-effective machine operation.

Low Investment, High Value

The Ecoplat Plus delivers strong returns for its price point, with robust construction, low maintenance, and efficient use of film. It’s an ideal entry point for businesses looking to automate pallet wrapping without sacrificing performance or reliability.