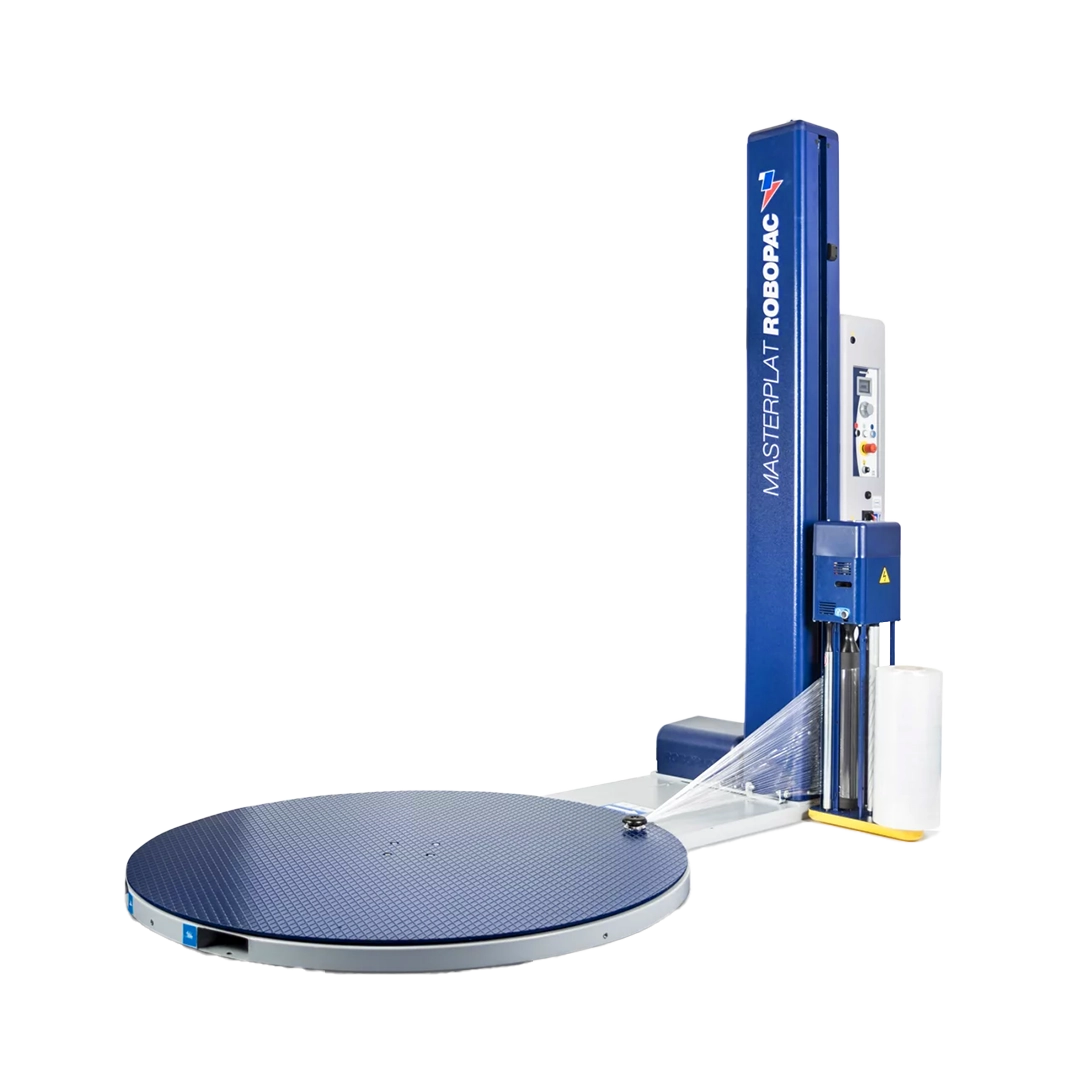

Reliable and Durable Construction

The Masterplat features a sturdy, high-capacity 65-inch turntable supported by 28 bearings, ensuring long-term reliability and structural integrity. Capable of handling loads up to 4,400 pounds, this robust construction ensures stable and secure wrapping, minimising downtime and providing dependable performance even in demanding environments.

Efficient PGS Film Carriage

Equipped with the PGS film carriage, the Masterplat delivers a fixed 250% power pre-stretch, significantly reducing film consumption while ensuring optimal load containment. The tension applied to the film is controlled electronically via a strain gauge, allowing precise adjustments directly from the control panel, resulting in consistently wrapped pallets and reduced material costs.

User-Friendly Control Panel

The intuitive control panel features the Master Jog Dial combined with a clear graphic display and user-friendly icons. This simplifies machine setup and allows operators to quickly select optimal wrapping parameters for various load types. This ease of use ensures consistent wrapping quality and minimal operator training time.

Advanced R-Connect Technology

Robopac’s R-Connect technology provides real-time usage and performance data through cloud connectivity. This advanced system significantly reduces downtime by providing critical operational insights, enabling remote monitoring, troubleshooting, and efficient maintenance planning. With R-Connect, businesses achieve higher productivity and lower operational costs.

Safety and Compliance

The Masterplat prioritizes operator safety with key features including an anti-fall device and pressure-activated safety stops on the film carriage. It meets stringent safety standards, being fully CE compliant, and UL and CUL certified, ensuring a secure operational environment for your packaging processes.

High Capacity and Flexibility

The Masterplat offers flexibility with adjustable wrapping speeds (5–12 RPM) and load heights (standard 86″, optional 110″), accommodating a wide range of pallet sizes and configurations. Its powerful 1 HP turntable drive ensures smooth and reliable operation, meeting the needs of high-volume packing environments with ease.