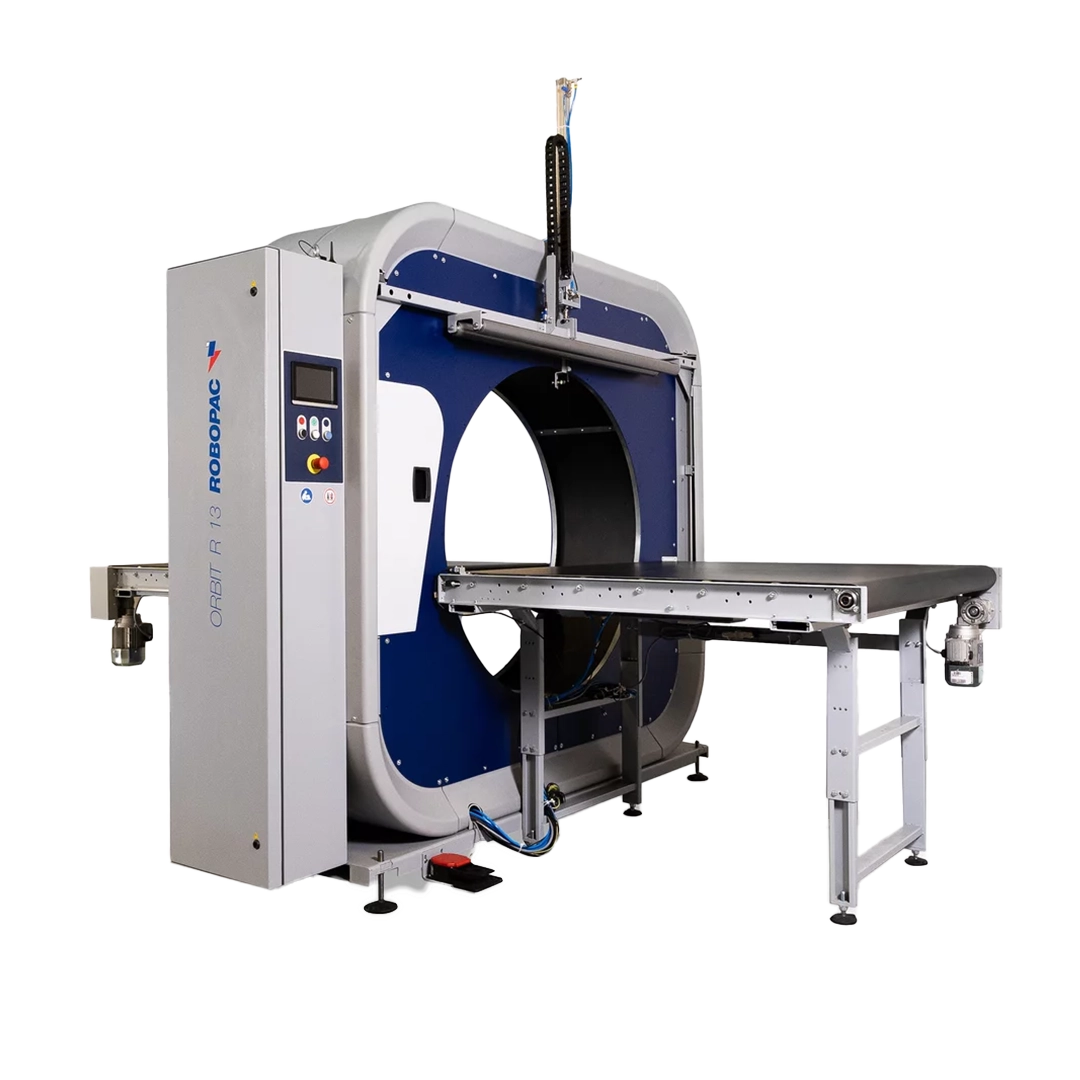

Efficient and Precise Wrapping

Orbital wrappers deliver efficient, consistent, and precise wrapping around products. The machine’s design allows for continuous film wrapping, ensuring a smooth and tight wrap every time. This precision prevents loose film, ensuring that the load is securely wrapped and protected during transportation, reducing the risk of product damage.

Ideal for Irregularly Shaped Products

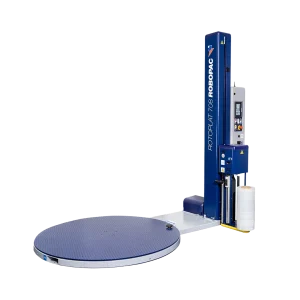

Unlike traditional wrapping methods, orbital wrappers are designed to handle products of varying shapes and sizes. Whether you’re working with large boxes, bundles of materials, or irregularly shaped items, the orbital wrapper wraps the product uniformly, making it an ideal solution for packaging items that cannot easily be handled by standard turntable wrappers.

Increases Packing Speed and Efficiency

Orbital wrappers are built for high-volume operations, allowing businesses to package large quantities of products quickly. The machine’s automatic wrapping process reduces labor time, increases throughput, and improves overall packing speed. This makes orbital wrappers a great choice for companies looking to enhance packing efficiency and reduce downtime during their production processes.

Reduced Material Waste

One of the key benefits of orbital wrappers is their ability to use stretch film efficiently, reducing the amount of material needed to secure a load. The machine applies just the right amount of film to tightly wrap the product, minimizing waste and making it a cost-effective solution for businesses looking to save on packaging material costs.

Durable and Reliable Performance

Orbital wrappers are designed for long-lasting durability and reliable performance. Built with heavy-duty components and engineered to handle continuous operation, these machines are ideal for demanding production environments where consistent wrapping quality and minimal downtime are crucial.

Versatile for Various Product Sizes

Orbital wrappers can accommodate a wide range of product sizes, from small packages to large, bulky goods. Adjustable settings allow the machine to be customized for different packaging needs, making it a versatile option for companies that handle diverse product lines and require flexibility in their packaging processes.