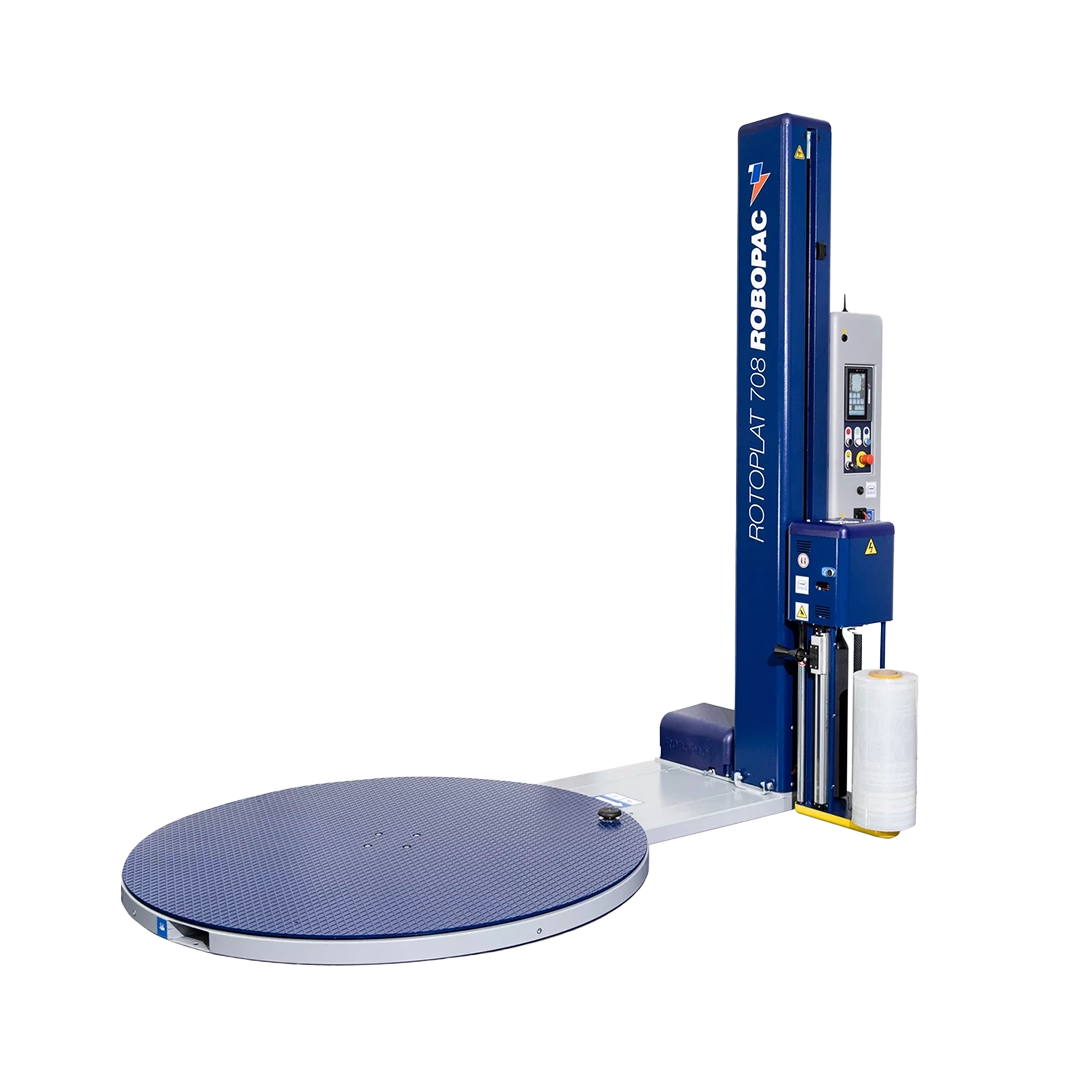

Consistent and Secure Packaging

Turntable wrappers provide consistent and secure packaging by rotating the product while stretch film is applied evenly around it. This ensures that the wrap is tightly secured, preventing shifting or damage during transit. The uniform application of stretch film also helps reduce the likelihood of product damage, making it ideal for businesses that need reliable, high-quality packaging.

Increases Efficiency and Speed

Turntable wrappers are designed for high-volume operations, allowing businesses to wrap products quickly and efficiently. The continuous rotation of the turntable combined with automatic film application increases packing speed, reducing the amount of time and labour required for each package. This helps businesses improve overall productivity and meet tight shipping deadlines.

Adjustable Settings for Various Product Sizes

Turntable wrappers feature adjustable settings that allow operators to customize the wrapping process to suit different product sizes. Whether you’re wrapping small boxes or large pallets, the settings can be easily modified to provide the optimal amount of film and tension for each load, ensuring the best possible protection for your products.

Durable and Reliable

Built with heavy-duty components, turntable wrappers are designed for long-lasting durability and reliable performance. These machines are ideal for continuous operation in busy environments, offering consistent wrapping quality and minimal downtime. Their robust construction ensures that they can handle large, bulky products and high-volume packing requirements without breaking down.

Cost-Effective Solution

Turntable wrappers provide a cost-effective solution for businesses looking to streamline their packaging process. By automating the wrapping process, these machines reduce the need for manual labour, helping businesses save on labour costs while ensuring that products are securely wrapped. Additionally, turntable wrappers optimise film usage, reducing waste and making them more affordable in the long run.

Improves Load Stability

Turntable wrappers provide excellent load stability by tightly wrapping products with stretch film. This helps keep goods secure and prevents them from shifting or toppling during transportation. The strong and consistent film ensures that the load remains intact, improving safety and reducing the risk of damage to the products or surrounding materials.