Reliable and Secure Sealing

Heat sealers are designed to create strong, airtight seals that ensure the integrity of your packaging. The heat and pressure applied during the sealing process ensure that the packaging stays secure, preventing contamination, spillage, or tampering. This reliability makes heat sealers essential for maintaining product quality throughout storage and transport.

Versatile for Various Packaging Materials

Heat sealers are compatible with a wide range of packaging materials, including polyethylene, polypropylene, laminates, and other thermoplastic films. Whether you’re sealing food bags, medical pouches, or industrial products, heat sealers provide a reliable and consistent seal for a variety of materials, making them a versatile tool for many industries.

Increases Packaging Efficiency

Using heat sealers in your packing process increases efficiency by automating the sealing task. Heat sealers provide a quick and consistent sealing process, reducing the time spent on manual sealing. This increases overall packing speed, enabling businesses to meet shipping deadlines and keep operations running smoothly.

Improves Product Freshness and Safety

By sealing packaging materials securely, heat sealers help extend the shelf life of products, especially in the food industry. The airtight seals protect products from moisture, air, and contaminants, preserving freshness, flavour, and safety. Heat-sealed packages are tamper-evident, ensuring that your products are safe and protected during storage and transport.

Easy to Use and Maintain

Heat sealers are designed to be user-friendly, with simple controls that make the sealing process easy to operate. Many models feature adjustable temperature settings to accommodate different packaging materials and sealing requirements. Additionally, heat sealers require minimal maintenance, with simple cleaning and occasional maintenance to keep them in good working condition.

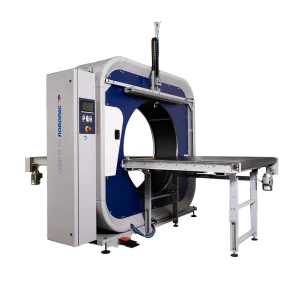

Variety of Models for Different Applications

Heat sealers are available in a variety of models to suit different packaging needs. Manual, foot-operated, and automatic models offer flexibility for businesses of all sizes and packaging volumes. Whether you’re sealing small batches or large-scale production runs, there’s a heat sealer model designed to meet your specific requirements.