Back to blog

PPWR REGULATION: HOW TO REDUCE PLASTIC AND MAINTAIN LOAD STABILITY

Written by

ELLIE CHALMERS

Load Stability

Table of Contents

Estimated read time: 20 mins

PPWR IS COMING: PREPARE YOUR PACKAGING OPERATION

By 2030, the Packaging and Packaging Waste Regulation (PPWR) will require packaging operations to use more recycled content in their supply chain.

For many businesses, this makes using recycled pallet wrap inevitable under the PPWR regulation, bringing with it fears of reduced film performance and poor load stability.

But with the right approach, reducing plastic could actually strengthen your operations, rather than compromise them.

Whether your goal is to cut plastic usage across the supply chain, or prepare for a safe transition to recycled pallet wrap, this guide reveals how to comply with PPWR and optimise performance.

What is PPWR Regulation?

PPWR stands for the Packaging and Packaging Waste Regulation (EU 2025/40). Its main objective is to drive higher post-consumer recycled content (PCR) in films on the EU market, replacing the previous Packaging and Packaging Waste Directive (94/62/EC).

Even though PPWR is an EU regulation, many UK businesses are choosing to align with it too. With the introduction of UK regulations like the Plastic Packaging Tax and Extended Producer Responsibility, sustainability and compliance clauses are fast becoming the norm.

If you supply goods into the EU, work with EU customers, or want to future-proof your packaging operation, PPWR-ready packaging brings a clear commercial advantage.

WHY PCR PALLET WRAP PERFORMANCE MATTERS

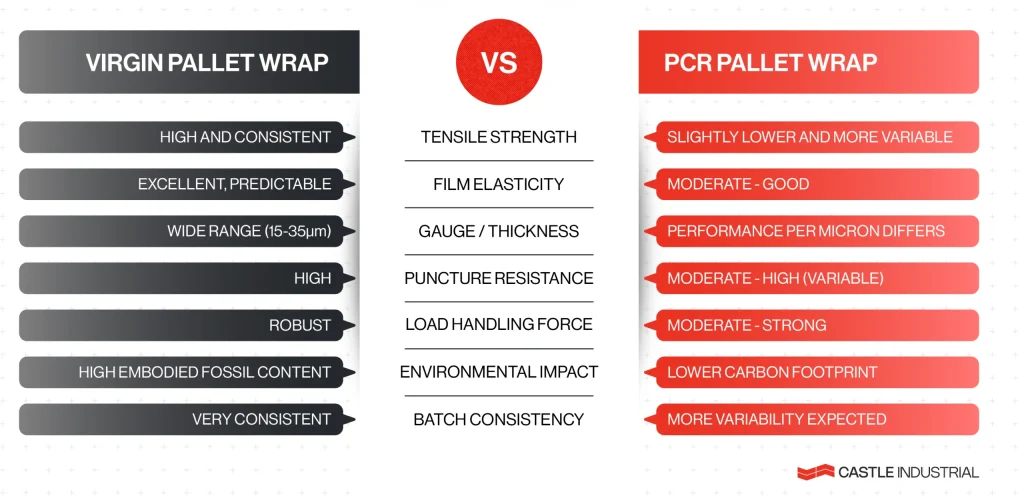

When measuring pallet wrap performance, your benchmark is likely to be a strong, stable load delivered safely. A common misconception is that higher recycled plastic content leads to reduced film performance, and ultimately damaged goods.

However, the truth is that not all PCR pallet wrap is made equal.

Low-quality PCR wrap can cause reduced cling, stretch and tensile strength, leading to collapsed pallets, delays, and wasted film. That’s why selecting a PCR wrap that performs well is vital.

Common PCR Performance Challenges

Variations in PCR performance typically depend on the supplier, the film’s percentage of recycled content, and your pallet wrapping method. To learn more about the different types of recycled pallet wrap, discover our post-consumer vs post-industrial wrap guide.

By understanding your PCR film performance (and adjusting your wrapping operation accordingly), poor PCR performance is not inevitable; it’s manageable.

THE HIDDEN OPPORTUNITY: OPTIMISING YOUR PACKAGING OPERATION

For businesses using plastic pallet wrap in their current packaging operation, switching to recycled pallet wrap is likely to be on the cards in the near future.

But complying with the PPWR regulations doesn’t have to be a mere compliance exercise, it’s an opportunity to improve your operation. Proactive audits, testing, and standardisation are key to staying ahead of PPWR requirements.

How to optimise operations for packaging waste compliance

Effective packaging waste compliance starts with robust film measuring and testing to ensure film performance takes priority over sustainability claims alone.

Key metrics to gather data on film performance include:

- Current machine settings (such as tension, overlap, wrapping patterns, and turn counts).

- Film usage (metres per pallet).

- Load shifts in transit (through tests like tilt vibration tables and lateral force simulators).

By combining the right film with the right settings, businesses can reduce plastic while maintaining consistent, secure pallets.

PRACTICAL STEPS TO PREPARE FOR PPWR

If you’ve made it this far, it’s likely you’re wondering how to comply with packaging waste regulations in practical terms:

1. Assess Your Current Packaging Operation

Start by auditing your current film usage and testing the stability of your wrapped pallet. Look for over- or under-wrapped pallets, and check machine settings for tension, overlap and speed. This will be important in selecting the right PCR for your setup.

2. Evaluate PCR Film Options

It’s essential to collaborate with suppliers to understand performance variations. A good supplier should be able to advise you on PCR film properties so you can wrap a stable, compliant pallet that’s also cost-effective.

Conduct small-scale pilot tests with different PCR formulations to ensure your load maintains integrity in real transit conditions, and collect damage rate data and staff handling feedback.

3. Test and Optimise with Expert Support

To get a true measure of PCR film performance, evidence-based testing is essential. Load Stability Test Centres allow businesses to implement new film and wrapping techniques with data-backed reports. This ensures PPWR-compliant pallets hit the road risk-free.

4. Document and Standardise Procedures

Efforts to meet packaging waste regulations fail when knowledge isn’t standardised. Create SOPs for PCR film handling and wrapping and keep records for PPWR compliance and continuous improvement.

PPWR is shaping the next era of stretch film, pressing brand owners to face the realities of PCR content and the impact that might have on their operations. It’s essential that any changes to process are made with stability in mind.

LIAM BLAND

TECHNICAL CONSULTANT

COMMON PPWR MISTAKES TO AVOID

Even the highest-performing PCR pallet wrap can fail when wrapped incorrectly. For businesses looking to comply with packaging waste regulations, don’t forget to avoid these common mistakes:

Switching to PCR pallet wrap without testing

There are often hidden variables that you can’t predict until you put your wrapped pallet to the test. Rigorous transport forces (like tilt vibration, breaking and acceleration) can be simulated at load stability testing centres, helping you spot potential problems or weak points well before they interrupt your supply chain.

Ignoring machine settings and wrapping patterns

Many operations switch from virgin to PCR wrap expecting the same performance, only to face load failures. The problem isn’t the film itself; it’s not adapting wrapping techniques to the new material. With proper testing and adjustments, PCR wrap can provide safe, stable pallets while reducing plastic use.

Over-stretching or under-applying film

In a bid to reduce pallet wrap usage, some operations over stretch or underapply their film, resulting in unstable loads and costly damages. The solution is better wrapping techniques and testing to find the right balance.

Failing to train staff

When wrapping changes aren’t embedded into everyday operations, performance can drift over time. Set clear standards to ensure that staff understand how to handle different film types, especially when a new film is introduced.

THE BENEFITS OF PROACTIVE COMPLIANCE

Taking a proactive approach to packaging waste regulations allows businesses to get ahead of the PPWR regulation requirements while delivering measurable operational benefits.

Improved load stability

- Optimised wrapping patterns and performance-tested PCR films help create stronger, more consistent pallets, reducing the risk of damage during transport.

- Fewer load failures mean lower claims, less rework, and improved customer satisfaction.

Audit-ready compliance

- Proactive compliance means documentation and traceability.

- Recording film usage, machine settings, and transport simulation data create audit-ready evidence that support both regulatory requirements and internal continuous improvement initiatives.

- This data-driven approach makes it easier to demonstrate compliance if regulations evolve or customers request proof of sustainable practices.

Ultimately, the PPWR regulation doesn’t have to be a threat. When addressed early, it presents an opportunity to align sustainability goals with operational excellence, enabling businesses reduce waste, control costs, and build a more resilient packaging operation for the future.

START PREPARING TODAY

While packaging waste regulations won’t be fully enforced till 2030, proactive testing and optimisation are key to ensuring a safe transition that keeps operations running smoothly.

Book a personalised session at Castle Industrial’s Test Centre to optimise your pallet wrapping process today.

Long-Term Pallet Wrap Storage: Expert Tips from the Warehouse

Written by

What Is Void Fill Packaging (and Does It Prevent Damage)?

Written by

What is The Safest Pallet Stacking Pattern

Written by

PPWR Regulation: How to Reduce Plastic and Maintain Load Stability

Written by

What is EPR? An Introduction to Extended Producer Responsibility

Written by

What is Stretch Film Memory?

Written by

Achieving the Rigid State with Stretch Film

Written by

Cutting-Edge Load Stability Techniques That Will Lower Your Packaging Expenses

Written by

How to Find the Right Pallet Wrap for Your Warehouse

Written by