Table of Contents

Estimated read time: 25 mins

INTRODUCTION

Collapsed pallets come at a cost. And while there are many factors influencing the stability of a stacked pallet, there’s one key player that’s often overlooked: the pallet stacking pattern.

The wrong stacking pattern can turn even the highest-quality pallet wrap into a wasted investment. With different weights, product sizes, and quantities, your pallet stacking pattern should be carefully considered to reflect this.

In this guide we’ll cover everything you need to know about pallet stacking patterns, with detailed diagrams, interlocking methods, and important safety tips. Plus, learn from our load stability experts on how to select the best pallet stacking pattern for your operation.

Wondering how high to stack your pallet? We have a guide for that too.

WHY PALLET STACKING PATTERNS MATTER

The way a pallet is stacked can directly impact whether goods arrive at their destination safely. Poor stacking patterns can lead to: load shifting, damaged products, reputational risks, wasted materials, and even injury to warehouse staff or drivers.

For UK and EU operations, standards like EUMOS 40509 and Directive 2014/47/EU mean companies must comply with load securing regulations to ensure safe transport. While specific stacking requirements vary by industry, the underlying principle remains constant: loads must be secured to prevent movement that could compromise safety.

That’s why choosing the right stacking pattern on a pallet is your first line of defence.

Pallet stacking patterns are fundamental to load stability. They can determine how weight is transferred through the whole pallet.

Correct pallet stacking reduces the risk of products moving during braking, acceleration and cornering, which ultimately reduces the risk of damage to the product.

WAYNE LAKEY

WAREHOUSE MANAGER

UNDERSTANDING THE TWO MAIN APPROACHES: COLUMN VS INTERLOCKING

Before diving into specific patterns, it’s important to understand the two fundamental approaches to pallet stacking: column stacking and interlocking. Each serve different purposes and suit different load types.

Column Pallet Stacking Patterns

Column stacking describes layers of boxes that are aligned vertically, pallet on pallet. Products are stacked directly on top of the ones below, ideal for stable, uniform boxes.

Key feature: Column stacking offers minimal overhang and enables fast, straightforward stacking. It works exceptionally well for stable, uniform boxes of identical dimensions. The vertical alignment means compression forces transfer directly downward, ideal for sturdy products that can bear significant weight.

When to use it: Column stacking is best suited for heavy, uniform loads where boxes have excellent compression strength. If your products are identical in size and can withstand vertical pressure, this pattern offers speed and simplicity.

Limitations: The trade-off with column stacking is reduced lateral stability. Because there’s no interlocking between layers, boxes can slide more easily if the load shifts during transport. This makes column stacking less suitable for mixed loads or products with varying dimensions.

Interlocking Pallet Stacking Patterns

Interlocked pallets are stacked in an offset pattern, ensuring each layer sits across the seams of the layer below. This results in a brick-like pattern that locks the boxes together. This approach distributes weight more evenly and significantly improves lateral stability.

Key features: The offset positioning prevents stacked pallets from sliding, as each box is partially supported by two or more boxes beneath it. This creates natural friction points that resist horizontal movement during transit.

When to use it: Interlocking patterns excel when dealing with mixed loads, uneven product dimensions, or situations where lateral stability is critical. They’re particularly valuable for lighter boxes that might shift easily, or when transporting goods over longer distances with multiple handling points.

Limitations: Interlocking patterns typically take more time to execute and require more careful planning. They may also create slight overhangs that need to be managed with appropriate wrapping techniques.

COMMON PALLET STACKING PATTERNS: A DETAILED BREAKDOWN

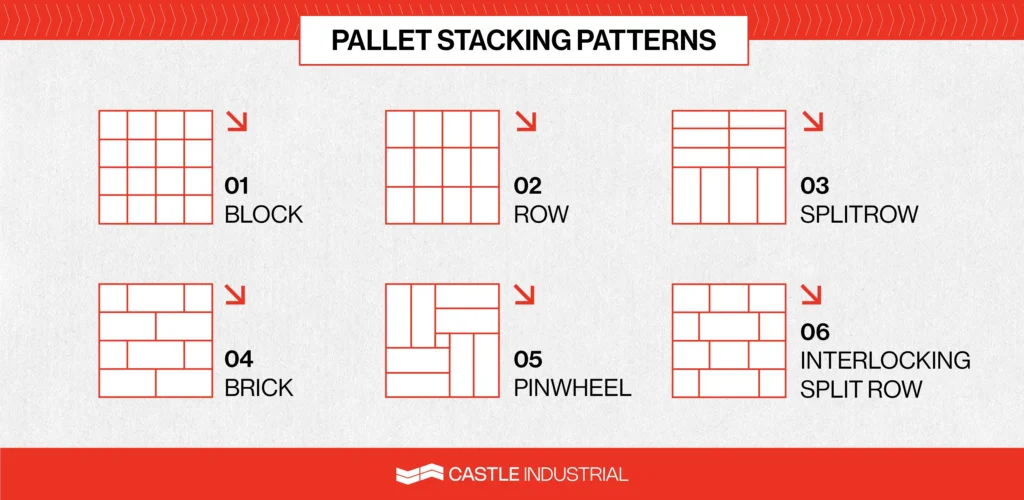

Now that we’ve covered pallet stacking basics, let’s examine the six most effective stacking patterns you can implement in your warehouse.

1. Block Stacking (Column)

Some large uniform products can be stacked in straight ‘block’ columns. This is perfect for heavy, bulky items that have substantial structural integrity and compression strength.

2. Row Stacking (Column)

Row stacking involves aligning boxes in straight, uniform rows with no offset between layers. Each box sits directly on top the one below, offering fast stacking but minimal lateral stability for identical products.

3. Split-Row Stacking (Hybrid Column)

Also known as ‘tired-column’ stacking, split-row stacking slightly offsets each layer while maintaining general vertical alignment. This is a middle ground that offers better lateral stability than pure column stacking.

4. Brick Pattern (Interlocking)

The brick pattern is one of the most common interlocking methods. Each layer is offset like bricks in a wall, creating maximum interlocking between layers. Brick patterns require boxes to be consistent dimensions for excellent all-round stability.

5. Pinwheel Pattern (Interlocking)

Sometimes known as chimney stacking, boxes are rotated 90° around a central point for the layer, creating a spiral appearance with a central void. This pattern is ideal for long, rectangular boxes or uneven loads.

6. Interlocking Split Row

This stacking pattern combines offset interlocking with partial row alignment, creating a balance of stacking efficiency and load stability. Interlocking split row stacking works well for moderately mixed loads that require safer stability and reasonable speed.

STEP-BY-STEP GUIDE: HOW TO STACK A PALLET SAFELY

Knowing the patterns is one thing, but implementing them correctly in your warehouse is another. Here’s how to stack a pallet safely, regardless of which pattern you choose.

Step 1: Choose the Right Pallet Type

First, select a pallet appropriate for your load weight and dimensions. Standard UK pallets suit most applications. Inspect for damage, broken boards, or protruding nails that could compromise stability.

Step 2: Inspect Products for Uniformity

Before stacking, check if boxes share identical dimensions and compression strength, and sort them by size and strength characteristics. This will help determine which stacking pattern suits your load best.

Step 3: Apply Your Chosen Stacking Pattern

For column stacking, align boxes precisely in straight rows with no gaps. For interlocking, offset boxes by half their length or rotate 90°, ensuring each row is positioned consistently.

Step 4: Secure the Load with Wrap or Strapping

Whether you’re using hand or machine wrap, apply the film to your stacked pallet from the base upward. We recommend assessing the film’s overlap and tension for optimised load stability, and consider corner boards for column-stacked loads.

To learn more about applying pallet wrap, discover our guide on stretching pallet wrap to its maximum potential.

Step 5: Verify Stability Before Transport

It’s vital to test the integrity of your chosen pallet stacking pattern before your load goes out on the road. Your pallet should feel solid with no movement, and be able to withstand vibration, acceleration and deceleration forces. If shifting occurs, rewrap or reconsider your stacking pattern choice.

To be confident your pallet stacking pattern is safe and road-ready, conduct load simulation testing to confirm you’re using the most appropriate stacking pattern.

BEST PRACTICES AND TIPS FOR WAREHOUSE SAFETY

Beyond choosing the right stacking pattern, several broader practices will improve safety and stability across your operations.

- Never mix product sizes within the same layer. Keep each layer uniform, even when combining different products on one pallet. Mixing sizes creates uneven surfaces that compromise stability in subsequent layers.

- Check floor and racking conditions regularly. Even perfect stacking won’t help if your warehouse floor is uneven or damaged. Inspect racking systems for signs of damage or overloading. A stable pallet on an unstable surface is still a safety hazard.

- Invest in staff training. Ensure warehouse staff understand why different patterns matter. Understanding the principles behind interlocking stacking patterns leads to better real-time decisions when facing unusual loads.

- Document and test your stacking methods. For recurring configurations, document which stacking pattern works best and why. Testing services like Castle Industrial’s allow businesses to obtain technical reports that definitively prove your methods are safe and compliant.

- Consider product placement strategically. Place heavier items on the bottom layers, and lighter products on top. This lowers the centre of gravity and improves overall stability.

Load shift in severe cases can unbalance a whole vehicle, causing road traffic accidents. When stacking a pallet, it’s important to have as much surface contact as possible, reduce empty spaces, and consider interlocking patterns like a brick wall to create friction.”

WAYNE LAKEY

WAREHOUSE MANAGER

FREQUENTLY ASKED QUESTIONS

Can you stack pallets on top of each other safely?

Yes, you can safely stack pallets on top of each other when loads are uniform, properly secured, and pallets have matching dimensions. Both products and pallets must have adequate compression strength to bear the combined weight. In warehouse storage, two – three pallets high is common.

When to avoid stacking pallets: Don’t stack pallets on top of each other if products are fragile, loads are uneven or poorly wrapped, pallet dimensions don’t match exactly, or you’re exceeding manufacturer weight ratings for your pallets or racking systems.

Which pallet stacking pattern is best for heavy loads?

Column stacking patterns like row stacking or block stacking are best for heavy, uniform loads with strong compression resistance. These patterns transfer compression forces directly downward, preventing lateral stress.

However, if heavy loads lack uniformity or will experience significant movement during transport, interlocking brick patterns may be necessary despite slower stacking speeds.

How do interlocking pallet stacking patterns improve stability?

Interlocking patterns improve stability by preventing horizontal movement between layers, as each box sits across the seams of the row below. This creates natural friction points that resist sliding, much like bricks in a wall. The result is superior lateral stability during transport, especially when vehicles brake, accelerate, or corner, while distributing weight more evenly across the pallet surface.

WHEN PROFESSIONAL TESTING MAKES THE DIFFERENCE

Even with the best stacking patterns and techniques, some loads present complex stability challenges. Perhaps you’re launching a new product line with unfamiliar dimensions, or you’re experiencing recurring transit damage despite your best efforts. This is where professional load stability testing proves invaluable.

At Castle Industrial, our free load stability testing centre provides technical reports that identify the optimal stacking pattern, wrap specification, and application method for your specific products.

Ready to eliminate pallet stability problems? Get in touch to learn more about our load stability testing services. Because when it comes to protecting your goods in transit, expertise matters.

What is The Safest Pallet Stacking Pattern

Written by

PPWR Regulation: How to Reduce Plastic and Maintain Load Stability

Written by

What is EPR? An Introduction to Extended Producer Responsibility

Written by

What is Stretch Film Memory?

Written by

Achieving the Rigid State with Stretch Film

Written by

Cutting-Edge Load Stability Techniques That Will Lower Your Packaging Expenses

Written by

How to Find the Right Pallet Wrap for Your Warehouse

Written by

Recycled Pallet Wrap: Post-Consumer vs. Post-Industrial Waste

Written by

What Is Directive 2014/47/EU?

Written by