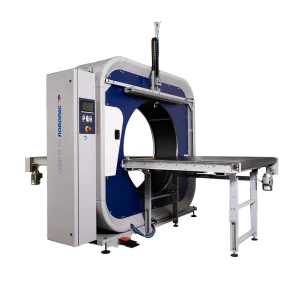

Tight, Secure Packaging

Heat shrink systems provide a tight, secure fit around your products by shrinking the film when heat is applied. This ensures that products are protected from damage, dust, moisture, and contaminants during storage and transit. The snug fit helps keep items in place, preventing shifting or movement within their packaging, which reduces the risk of damage.

Professional and Presentable Appearance

Heat shrink systems offer a clean, professional appearance for packaged products. The shrink film conforms tightly to the product, creating a smooth and polished look that enhances the product’s presentation. This is particularly valuable for retail products where packaging aesthetics play a key role in consumer appeal and branding.

Tamper-Evident and Protective

Heat shrink systems provide tamper-evident packaging, which makes it easy to detect if a product has been opened or altered. The tight-fitting shrink wrap also acts as an additional protective layer, safeguarding the product from external factors like moisture, dust, or dirt, ensuring that the product arrives in optimal condition.

Versatile for Various Product Sizes and Shapes

Heat shrink systems are versatile and can accommodate a wide range of product sizes and shapes, from small items like cosmetics to larger products like boxes or bottles. Adjustable settings allow operators to customize the shrinking process to suit different packaging requirements, making these systems ideal for businesses with diverse product lines.

High-Speed and Efficient

Heat shrink systems are designed for high-speed, continuous operation, making them perfect for high-volume packaging environments. With automatic or semi-automatic features, these machines can quickly and efficiently wrap large quantities of products, increasing throughput and reducing packaging time in production lines.

Easy to Use and Maintain

Heat shrink systems are user-friendly and easy to operate, with simple controls and settings that allow for quick adjustments. They are also easy to maintain, requiring minimal downtime for cleaning and servicing. This ease of use and low maintenance make heat shrink systems ideal for businesses of all sizes, from small-scale operations to large industrial applications.