Unfortunately, in the bustling world of industrial work, where sharp tools and heavy machinery are part of the daily grind, hand injuries are all too common. Supplying a number of sectors within the industry for close to three decades, we know how important it is to protect your most valuable tools – your hands.

So that’s what we’re going to focus on in this article, and how you can mitigate risks by wearing cut resistant gloves…

Understanding the Need for Cut Resistant Gloves

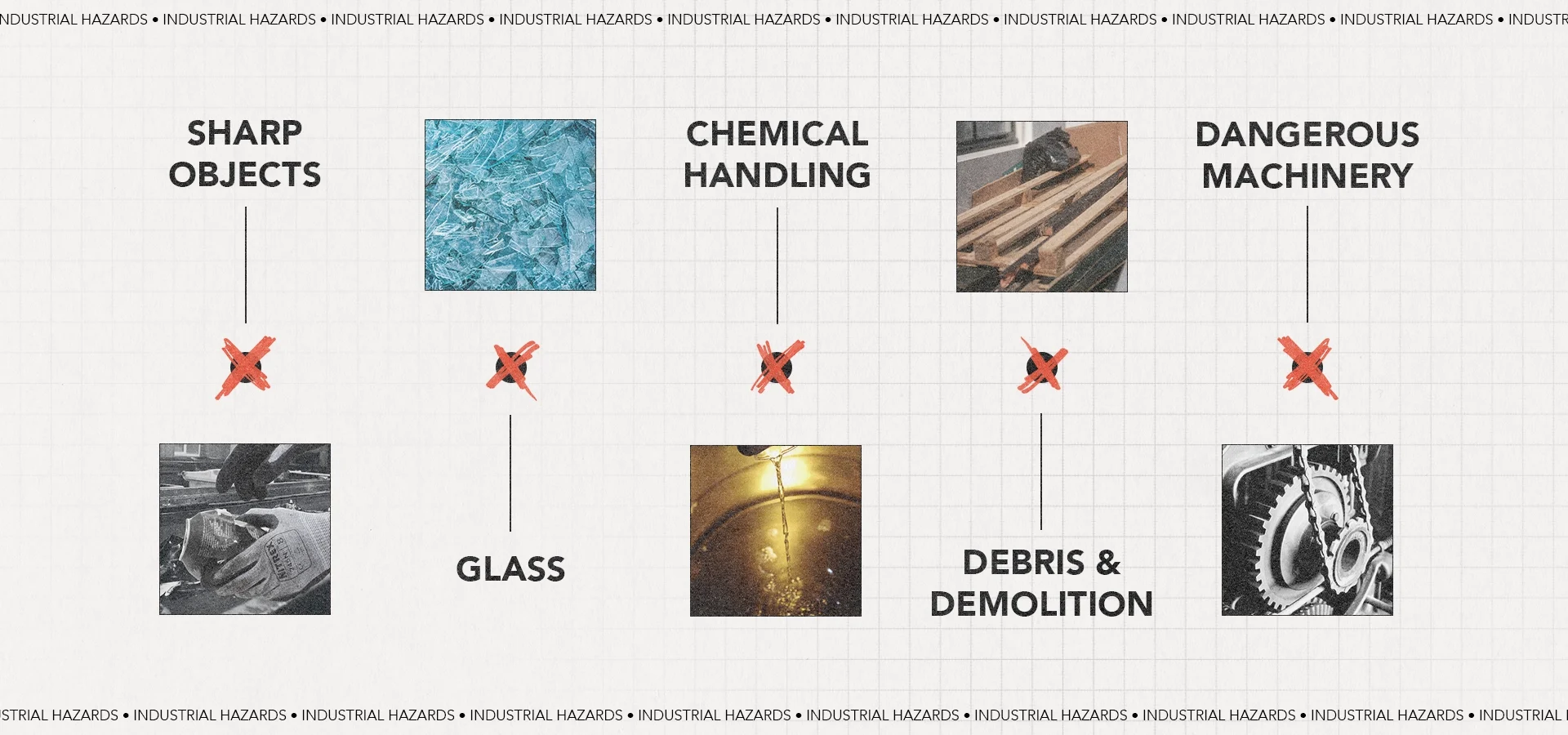

Common Hazards in Industrial Environments

Industrial environments are rife with hazards that can lead to serious hand injuries. Whether you’re handling sharp tools, working with glass or cutting metals, the risk is ever-present. It only takes one slip for you to be dealing with deep cuts or lacerations.

The Impact of Hand Injuries

Hand injuries aren’t just painful; they can be both costly and debilitating. A deep cut might require stitches, which can lead to lost workdays. Moreover, the operational impact can be significant. With a worker sidelined by injury, productivity will inevitably drop and projects can fall behind schedule.

What Are Cut Resistant Gloves?

Cut resistant gloves are specially designed PPE that provides enhanced protection against cuts, lacerations, and punctures. These gloves are made from advanced materials which are woven together to create a protective barrier. The level of protection varies, with gloves rated on a scale according to the EN 388 standard in Europe or the ANSI/ISEA levels in the United States.

Key Features of Cut Resistant Gloves

Fit and Comfort

One of the most critical aspects of any protective glove is how well it fits. Gloves that are too tight can restrict movement, while those that are too loose can slip off or interfere with handling tools. Another key consideration is comfort, particularly for those who will be wearing gloves for extended periods. It’s important to consider gloves with designs that offer flexibility and do not hinder dexterity.

Grip and Durability

As well as the aforementioned, a quality pair of gloves will also provide excellent grip. This is essential when working with slippery materials or in wet conditions. Additionally, durability is crucial. Industrial work can be tough on gloves and you’ll no doubt want a pair that can withstand the rigours of daily tasks without wearing out quickly.

Breathability

If you’ve worked in hot environments, you’ll know already just how important breathability is. Thick, heavy gloves can lead to sweaty, uncomfortable hands which increase the likelihood of slips. Breathable materials therefore are a key consideration if you’re working in these settings.

Choosing the Right Cut Resistant Gloves for Your Job

Assessing Workplace Hazards

The first step in choosing the right gloves is to assess the specific hazards in your workplace. Are you handling sharp metal, glass, or something else entirely? Each material poses different risks, and you’ll need gloves that offer the appropriate level of protection.

Matching Gloves to Job Requirements

Once you understand the hazards, you can match the glove specs to your job requirements. For instance, if you’re dealing with high-risk materials, opt for gloves with a higher cut resistance rating. Additionally, consider any additional protection you might need, such as impact resistance or chemical resistance too.

Proper Sizing and Fit

As alluded to earlier, the importance of sizing cannot be overstated. Gloves that fit well provide better protection, are more comfortable to wear and reduce the risk of slips. Most manufacturers offer sizing charts to help you find the right size, so be sure to reference that on your order. Don’t be tempted by ‘one size fits all’ solutions – they rarely do.

Proper Use and Maintenance of Cut Resistant Gloves

Best Practices for Wearing Gloves

To get the most out of your cut resistant gloves, you must follow best practices for wearing them. Always ensure they have a snug fit and be sure to check them for any signs of damage before use. A glove with a small tear or hole can’t be expected to provide full protection.

Maintenance Tips

To extend the life of your gloves, proper maintenance can be useful. Regularly clean your gloves according to manufacturer instructions. Typically, this involves washing them with soap and water. Proper storage is also key to consider; keep your gloves in a cool, dry place away from direct sunlight.

When to Replace Your Gloves

No matter how well you maintain your gloves however, they will eventually wear out. Signs that it’s time to replace them include visible wear and tear, loss of flexibility or diminished grip. Never compromise on safety; when in doubt, replace your gloves.

Conclusion

Hand safety in industrial settings is non-negotiable. Cut resistant gloves offer a simple yet effective solution to prevent injuries and keep workers safe. Investing in high-quality gloves makes a significant difference to both workplace safety and productivity.

Don’t wait for an accident to happen — protect your hands today!

Call 01524 734040

Call 01524 734040  Email sales@castleindustrial.com

Email sales@castleindustrial.com  We're here Monday to Friday 7am - 5pm

We're here Monday to Friday 7am - 5pm