What does successful distribution look like to you?

On time? Low cost? Sure, they’re part of the equation but in today’s blog, we’re talking about goods arriving safely and without damage. More specifically, we’re talking about the impact foam packaging could have on your operations. We’ll be breaking down its features, benefits and how switching can mitigate damages we see all too often.

Understanding Foam Packaging

What is Foam Packaging?

Made from a variety of foam materials, foam packaging is designed to cushion and protect products during shipping and handling. The materials most commonly used include; polyethylene (PE), polyurethane (PU), and expanded polystyrene (EPS). Each of these types has unique properties that make it suitable for different applications. For instance…

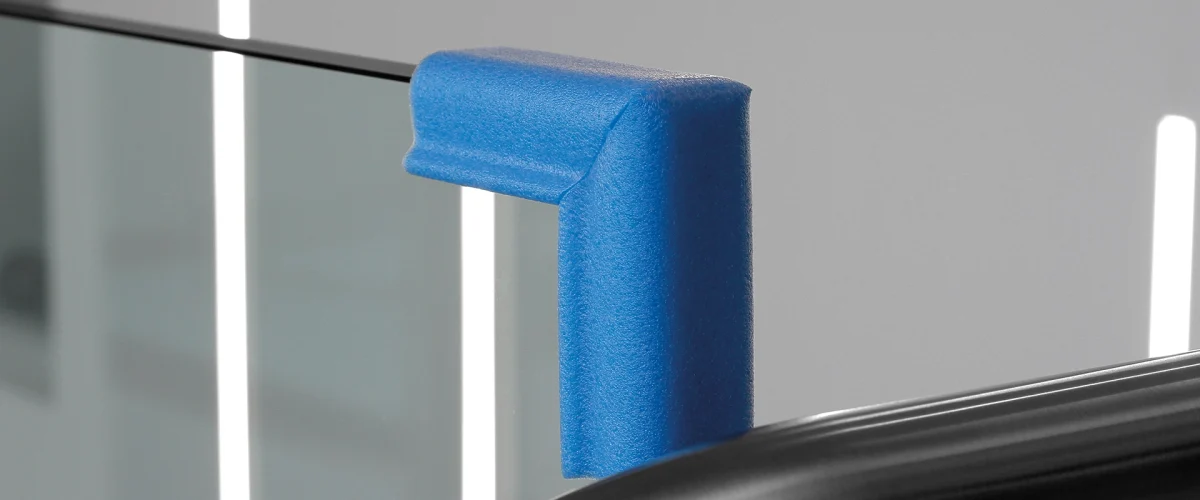

Polyethylene (PE): Great for surface protection and shock absorption. You will often see this used to package fragile items such as glass and homeware.

Polyurethane (PU): Polyurethane is a brilliant shock absorber, which is why you’ll often find it used as an insert or lining in packaging.

Expanded Polystyrene (EPS): Commonly used in electronic packaging to provide rigidity to packaging and compression protection for high value goods.

Benefits of Foam Packaging

Foam packaging offers several benefits that make it a preferred choice for many industries:

Protective Qualities: Foam packaging provides excellent shock absorption, preventing damage during transit.

Versatility: Foam can be moulded or cut to fit any shape, making it ideal for protecting a range of products from delicate electronics to heavy machinery.

Lightweight: Foam packaging adds minimal weight to shipments, reducing transportation costs.

High Performance Foam Materials

Thermal and Acoustic Insulation

One of the standout features of foam packaging is its thermal and acoustic insulation. These features not only protect products from fluctuations in temperature but reduce noise during transport too.

Thermal Insulation

Foam packaging materials offer significant thermal insulation, which is crucial for products sensitive to temperature changes. For example, in the pharmaceutical industry, medicines are often transported with foam to ensure it remains within the required temperature range during transit.

Acoustic Insulation

Noise can also be a concern, especially for fragile items. Foam’s acoustic insulation properties help in reducing the impact of vibrations and external noise, ensuring that delicate items reach their destination intact. Think high-end audio equipment or precision instruments – they require that extra layer of protection that foam packaging is able to provide.

Specific Applications in Various Sectors

Foam packaging is not a one-size-fits-all solution and can have specific applications tailored to different industries:

Civil Engineering

In civil engineering, foam materials are used for thermal insulation in buildings and noise reduction in public spaces. This helps create more energy-efficient and quieter environments.

Medical Applications

Medical equipment and supplies require stringent protection. As mentioned earlier, foam packaging ensures sensitive medicines are protected from impact and contamination during shipping.

Transport Industry

From automobiles to railways, foam packaging plays a crucial role in reducing vibrations and protecting components. It’s used in everything from car seats to structural foam in vehicles, ensuring safety and comfort.

Addressing Common Pain Points

Price Increases

Despite initial investment, foam packaging can prove to become a cost-effective solution in the long run. By reducing damage rates and returns, foam can save your business, not just from replacing products, but reputational and supply chain damage too. A company we supply foam packaging to regularly boast a significant reduction in damages, saving untold amounts in the years since.

Ensuring Safe Delivery

Ensuring the safe delivery of products is critical. Foam packaging’s high absorption values make it the standout choice for distributing delicate items, such as glassware or electronics.

Consistency in Quality

Consistency in the quality of protective products is vital. Substandard alternatives can lead to high damage rates, affecting customer satisfaction and increasing costs. Foam packaging, like our remarkable supply of NOMAPACK, is manufactured under strict quality controls, ensuring that each piece provides the same level of protection. This consistency helps in building a reputation for reliability.

Substandard Alternatives

Inferior protective products can be tempting due to lower costs, but they often lead to higher damage rates. Investing in high-quality foam packaging ensures that your products are well-protected, reducing the likelihood of costly damages.

Specialised Foam Applications

Protective Profiles and Structural Foam

Our supply of versatile foam packaging from NMC, provides profiles that are lightweight, stable and chemically neutral, which makes them a standout choice for a variety of applications. In fact, NMC actually provide tailor made formulations which can provide a bespoke material optimised to your packaging needs.

Check out their materials page here, to learn more.

Environmental Benefits

Our choice of foam packaging are designed to be ecologically friendly, with many options available that are recyclable or at least made from recycled materials. This not only helps in reducing waste but meeting regulatory requirements and improving your company’s environmental footprint.

Selecting the Right Foam Packaging

Custom Solutions

Choosing the right foam packaging involves understanding your specific needs. Custom solutions tailored to your products ensure optimal protection. Therefore, we suggest booking time to talk about your operations with one of our packaging specialists. You can arrange that for a time that suits you bets by heading to the Castle scheduler here.

Conclusion

Foam packaging is an indispensable tool in ensuring the safe delivery of products while addressing key pain points in the logistics and manufacturing industries. By understanding its benefits and applications, you can make an informed decision to enhance product safety, quality consistency, and cost-effectiveness.

If you’d like to learn more, or arrange a meeting with one of our packaging specialists, you can do that by using the aforementioned scheduler, or alternatively calling us today on 01524 734040.

Call 01524 734040

Call 01524 734040  Email sales@castleindustrial.com

Email sales@castleindustrial.com  We're here Monday to Friday 7am - 5pm

We're here Monday to Friday 7am - 5pm