An Expert Guide for Warehouse and Logistics Professionals

In the fast-paced world of warehousing and logistics, optimised packaging is essential to the smooth running of supply chains – ensuring your goods arrive in full, and on time at their destination.

One key tool in the arsenal of all free-flowing distribution centres is pallet wrap, which is used to secure goods during transport and storage. In this blog, we’re uncovering some of the key differences between its two primary types: cast film and blown film.

We’ll look at how each are made, their characteristics and most importantly, how you can choose the right one for your operations. So, without further ado, let’s get started…

Understanding Cast and Blown Film

What is Cast Film?

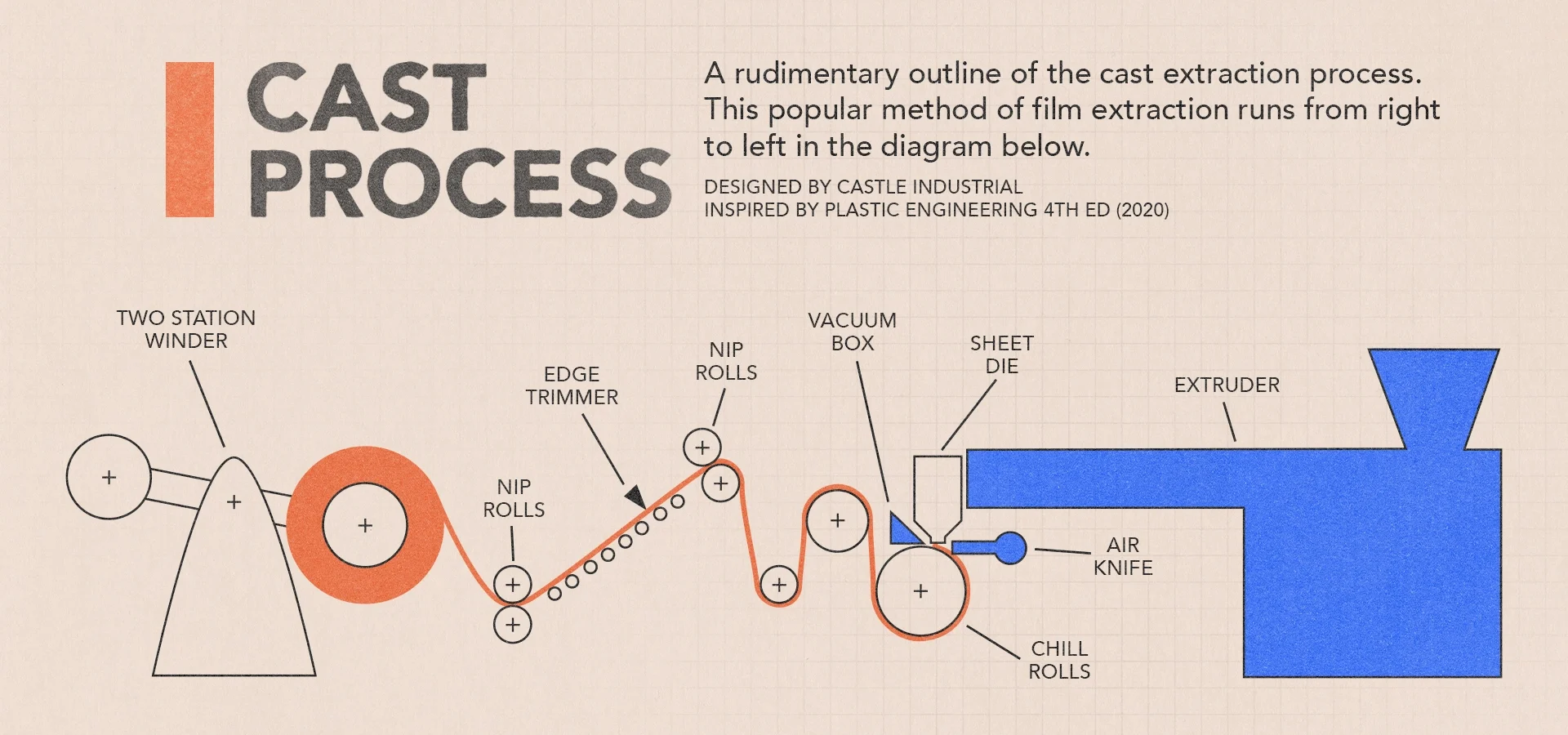

Produced through a process called cast extrusion, cast film is by far the most common film on the market. The process used to create it involves melting down plastic pellets, then extruding them through a flat die. The film is then quickly cooled by passing it over chilled rollers, which gives it its characteristic clarity and smooth finish.

Key Characteristics:

– Clarity: Cast film is incredibly clear, making it easy to see what has been wrapped inside. This is particularly useful for inventory management and barcode scanning.

– Stretchability: This film stretches easily, providing excellent load stability with less force.

– Quiet Unwinding: One of the notable benefits of cast film is its quiet application, which can be a significant advantage in a busy warehouse environment.

What is Blown Film?

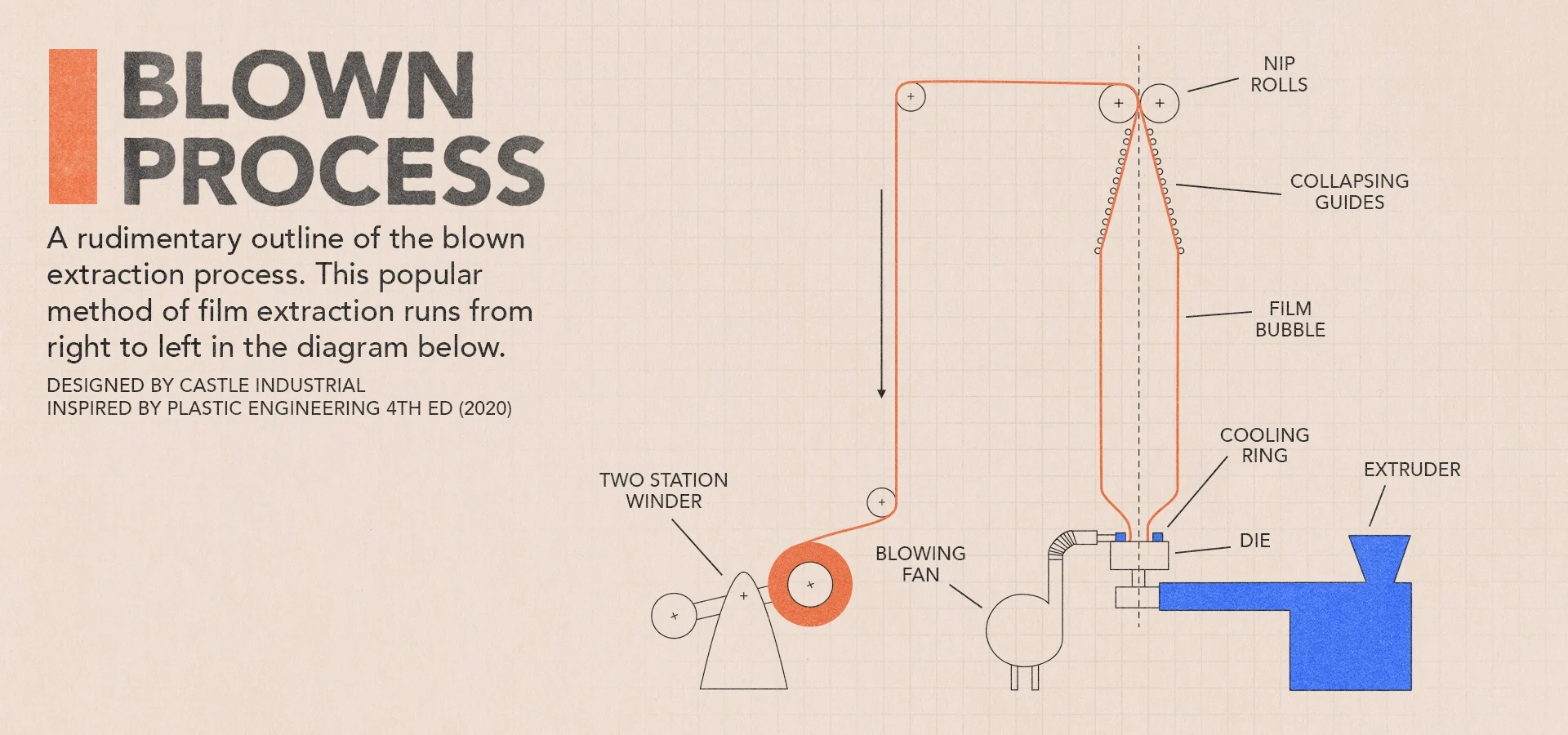

The more traditional of the two forms, blown film is produced though a process called blown extrusion (or Tubular Film Extrusion). In this method, resin beads are melted and extruded through a circular die to form a thin-walled tube. That tube is then inflated into a bubble, passed through ‘nip rolls’ to create ‘lay flat tubing’ and eventually wound into rolls.

Key Characteristics:

– Strength and Puncture Resistance: Blown film is known for its superior strength and puncture resistance, making it ideal for heavy or sharp-edged loads.

– Tackiness: It has a naturally higher level of tack, which helps the layers stick together better, enhancing load stability.

– Noise Level During Application: Unlike cast film, blown film can be noisier during application, which might be a consideration depending on your work environment.

Performance Comparison

Strength and Durability

When it comes to strength and durability, blown film is the obvious choice. Its robust construction makes it less likely to tear or puncture, which is crucial when dealing with heavy or oddly-shaped loads. Traditionally, you’d see many sellers suggest moving to blown if you have unorthodox pallets, however, products like our innovative range of nano films have completely changed this approach as they offer the best of both cast and blown.

Clarity and Visibility

For businesses where visibility is key, cast film is the clear winner. Its transparency makes it easy to read labels and scan barcodes without removing the wrap. If your business is still using blown films, you’ll notice a significant improvement to your inventory management, as workers can quickly identify products without unwrapping pallets.

Stretchability and Elasticity

Both cast and blown films offer good stretchability, but they do behave differently under stress. Cast film stretches easily and consistently, making it simpler to achieve a tight wrap with less effort. Blown film, while stronger, requires a lot more force to stretch but offers great retention force, which keeps loads more stable over time.

Practical Considerations

Cost Effectiveness

Cost is always a significant factor to any warehouse and logistics leader. The answer is fairly clear cut as well, cast film typically costs less due to its much simpler manufacturing process. However, as we’ve mentioned earlier in this blog, considering our nano film range could provide added protection and stability to your loads, which could generate significant savings in damages over time.

Ease of Use

In a busy warehouse, ease of use can be a dealbreaker. Cast film is easier to apply, thanks to its stretchability and quiet unwinding. Blown film, though much more robust, is incredibly loud by comparison and requires some stress to apply effectively.

Environmental Impact

Sustainability is increasingly important in today’s business landscape, and though both cast and blown films can be recycled, blown film’s durability means less waste overall. However, it could be said, that because of the manufacturing process involved and reductions in application efficiency, it balances out.

There are recyclable versions available of each, here at Castle Industrial we can provide films from both types that have over 30% recycled material to mitigate the UK’s Plastic Packaging Tax.

Conclusion

As with anything, choosing between cast and blown film really depends on your specific needs and priorities. Cast film offers clarity, ease of use and cost effectiveness, therefore is the standout choice for the strong majority of the market. However, with its superior strength and puncture resistance, there is still a place for blown film.

Both however, are coming up against fresh competition in nano film, a highly versatile wrap that offers superior stretch and strength to match.

If you’re considering your options, be sure to schedule a call with our load stability team by using the link here.

FAQs

What if I need both strength and clarity?

Our innovative line of nano films provide the best of both worlds. Utilising state of the art nanotechnology, nano films are a fully optimised and the industry leading option.

How can I reduce noise during application with blown film?

Using pre-stretched blown film or investing in quieter wrapping equipment can help reduce noise levels during application.

Are there eco-friendly options available?

Yes, many manufacturers now offer eco-friendly films, including those made from recycled materials or biodegradable options. At Castle, we offer films made from at least 30% recycled material, so UK businesses can navigate past the Plastic Packaging Tax.

Call 01524 734040

Call 01524 734040  Email sales@castleindustrial.com

Email sales@castleindustrial.com  We're here Monday to Friday 7am - 5pm

We're here Monday to Friday 7am - 5pm